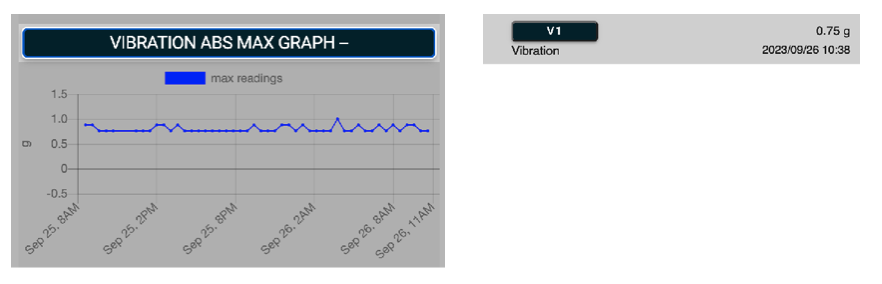

Mechanical issues don’t happen all at once—they build up gradually, often revealed by subtle shifts in vibration. Wave9’s built-in vibration monitoring detects these early warning signs to protect your equipment, avoid shutdowns, and reduce unplanned maintenance.

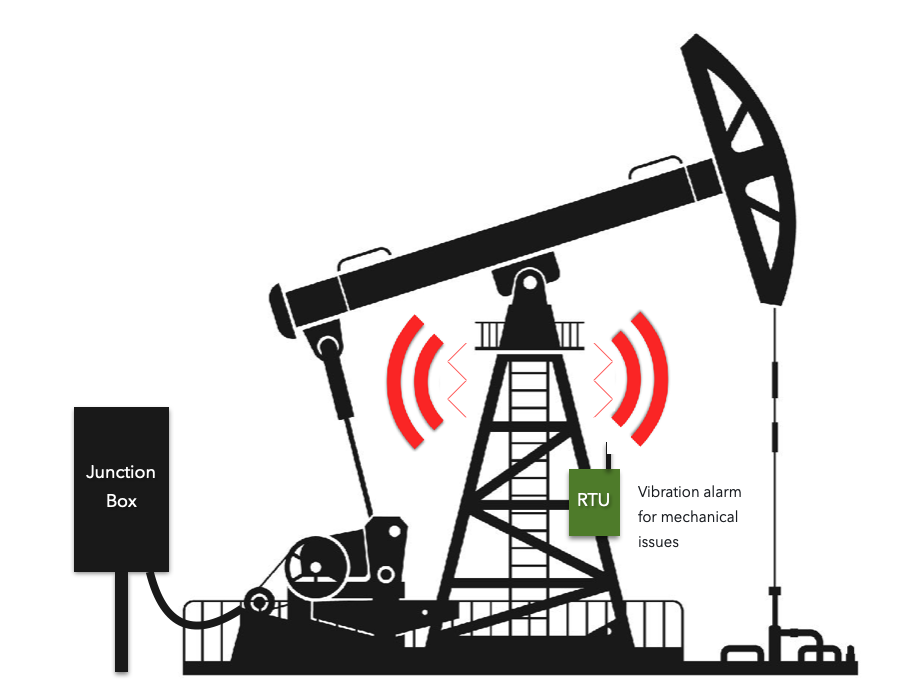

Built-in Vibration Sensors in the RTU

Wave9’s Remote Terminal Units (RTUs) come equipped with 3D internal vibration sensors. These continuously capture data about movement and impact events across your equipment—without requiring additional third-party hardware.

Alarms for Impact or High Vibration Events

When vibration spikes or patterns exceed safe operating thresholds, the system triggers immediate alarms. This provides field teams with a chance to investigate issues like worn bearings, misalignment, or cavitation—before they result in mechanical failure.

Optional Shutdown Integration

In critical applications, vibration data can be tied to automated shutdown logic. This means equipment can be stopped to prevent damage or injury when dangerous conditions are detected—without waiting for manual intervention.

Catch problems early. Wave9’s vibration detection transforms minor vibrations into actionable insights, keeping your equipment safe and productive.