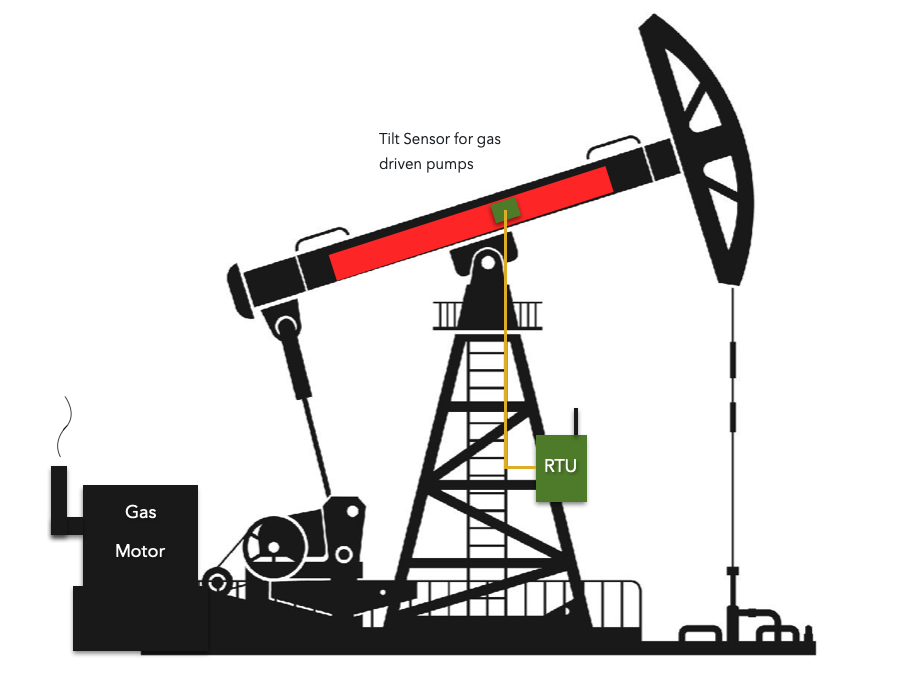

For gas-driven pumpjacks, traditional monitoring methods often fall short. Operators are left guessing whether equipment is functioning efficiently—or at all. Wave9’s motion detection technology changes the game with tilt sensor-enabled insights that help producers eliminate blind spots and respond to problems quickly.

Monitor Gas Pumpjack Motion with Tilt Sensors

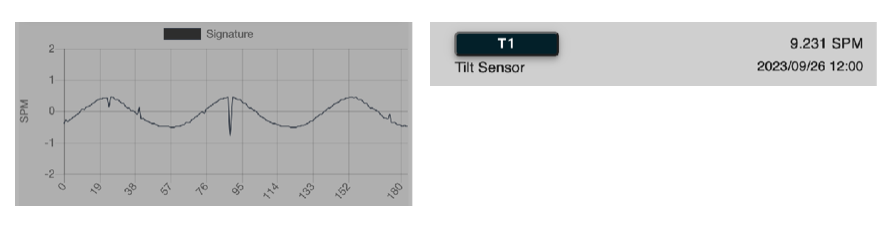

Unlike electric pumps, gas-driven systems don’t always have easily accessible data sources. That’s why Wave9’s motion detection uses a dedicated tilt sensor to track the movement of the pumpjack beam in real time. This enables precise tracking of strokes per minute, allowing operators to verify that a pump is working correctly—without having to drive to the site.

Immediate Alerts for Low Stroke Rates

If stroke counts fall below expected levels, or if vibration anomalies are detected (suggesting tapping or intermittent failures), the platform issues immediate alerts to field staff. This capability ensures that downtime events and mechanical inefficiencies are flagged early, before they lead to production loss or equipment damage.

Proactive Maintenance and Pump Optimization

By monitoring movement patterns continuously, operators can use stroke data trends to schedule proactive maintenance—adjusting gas supply, verifying valve integrity, or servicing equipment before it breaks down.

Whether you’re managing dozens of gas-driven sites or just a few remote pumps, Wave9’s motion detection ensures you’re always in the know.Stop flying blind with gas-driven equipment. Get real-time visibility and alerts with Wave9’s motion detection and ensure your pumpjacks are always working as they should.