In oilfield operations, mechanical issues can lead to major losses. Wave9’s advanced power monitoring capabilities empower producers to optimize performance, reduce downtime, and improve the management and maintenance of their extraction equipment.

Real-Time Visibility into Pump Health

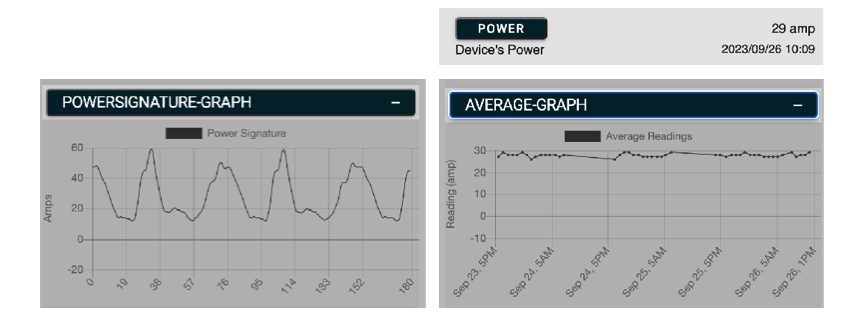

By analyzing current draw at the drive motor, Wave9 provides real-time insights into the operational status of pumpjacks, progressive cavity pumps (PCP), and electric submersible pumps (ESP). Operators can quickly detect whether equipment is functioning as expected, intervene immediately when needed.

Alarms for Immediate Action

Unplanned stoppages are costly. Our platform issues automatic alarms when it detects abnormal power delivery, alerting staff to pump stoppages and helping identify abnormalities. This early warning system ensures timely response before issues escalate into production halts.

Full Cycle Signature for Diagnostics

Wave9 captures the entire power signature of the pump cycle, providing rich data for diagnostics. This helps teams pinpoint issues like pump failure, overload, or inconsistencies in the mechanical system, leading to better maintenance and production decisions.

Pumpjack Balance Monitoring

An unbalanced pumpjack wastes energy and damages equipment. Our monitoring system provides visibility into counterbalance settings and power consumption, so operators can tune their equipment for optimal mechanical efficiency and lower power use.

Fill and Pump-Off Insights

Wave9 also offers insights into pump fill and off conditions using power signatures and optional load cell data. Field teams can identify when a pump is running dry or inefficiently filled — avoiding energy waste and protecting assets from unnecessary strain.Take control of your power data. Wave9’s platform turns electrical insights into operational excellence, helping you lower costs and extend asset lifespan.