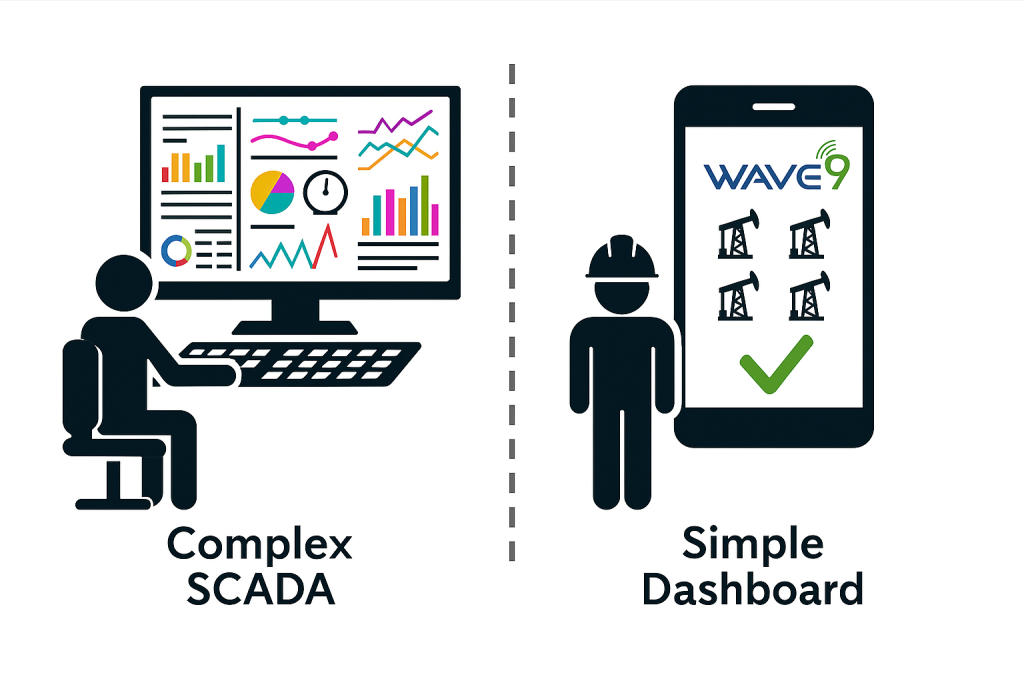

Producers increasingly face the same issue: SCADA holds the right data, but operators and supervisors often can’t access it when they need it. Critical information stays inside the control system, while field teams work with partial visibility. This slows decisions, delays responses to alarms, and forces engineers to relay routine updates.

As operations expand, this gap becomes more obvious. SCADA remains essential, but its workstation-bound design does not match how field teams work today. Wave9 closes this gap without replacing the control systems producers already rely on.

Where SCADA Fits and Where It Falls Short

SCADA provides the real-time data operations depend on pump status, pressures, alarms, and trends. Engineers use it daily for analysis and troubleshooting. But because SCADA was built for centralized control rooms, several limitations appear across most operations:

-

- Limited mobile access to data: SCADA is primarily desktop-based. Field operators often lack quick access to well status and alarms when they’re away from a workstation.

- A Complex Interface for Non-Engineers: SCADA screens are dense and technical. Supervisors and external stakeholders need simplified views, not full engineering dashboards.

- Alarms contained inside the control system: SCADA alarms usually stay inside the system and may be seen late or only after an operator reaches a computer. Without mobile alerting response times can slow down, increasing downtime and risk.

- Operational data stored outside SCADA: Maintenance logs, sensor readings, field notes, and contractor updates often sit in different tools. Operators must piece together information from multiple systems.

- Difficulties Sharing Data Securely: Stakeholders outside engineering often need visibility but can’t access SCADA directly. Many teams rely on screenshots or manual exports, which slows communication.

These constraints highlight the need for a system that makes SCADA data practical and accessible for everyday field work.

Extending SCADA With Modern Data Systems

Wave9 improves how teams use SCADA data while keeping the existing control system untouched. The objective is to make operational information accessible, organized, and secure.

Mobile access for field operators

Operators can view well status, trends, and alarms from their phone before driving to site. This reduces unnecessary trips and speeds up initial assessment.

Simple, visual data for all users

Users see only what’s relevant to their responsibilities. Supervisors get production summaries, operators get actionable well views, and leadership gets high-level insight.

Instant SCADA alarm notifications

Alarms are pushed directly to mobile devices. This reduces reaction time and helps ensure issues are handled promptly.

A unified operational view

Wave9 combines SCADA outputs with other key data sources, including:

-

- maintenance logs

-

- IoT sensor data

-

- field notes

-

- SCADA inputs

-

- SCADA exports

-

- Spreadsheet-based records

Teams no longer need several applications to understand a single well’s status.

Secure integrations engineered for industrial environments

Wave9 follows a security model consistent with modern cloud and control-system requirements:

-

- Token-authenticated endpoints

-

- Encrypted communication (HTTPS/SSL)

-

- Isolated data pipelines per client

-

- Support for CSV snapshots or JSON real-time updates

This allows SCADA data to be accessed safely without exposing the control network.

Why Producers Adopt This Approach

Wave9 users point to these benefits:

-

- faster response to alarms

-

- clearer communication across field and office

-

- reduced downtime

-

- fewer unnecessary site visits

-

- better decision-making for supervisors and leadership

-

- simpler sharing of well information without opening SCADA to external users

SCADA remains the source of truth. Wave9 ensures the right people can actually use that information when it matters.

A More Practical Way to Use SCADA

SCADA will continue to be the primary control system for artificial lift and well monitoring. The challenge is not data availability, it’s accessibility. Teams need operational information delivered consistently, in the field, and in a format they can act on immediately.

Wave9 provides that layer. It improves visibility, accelerates response, and supports more efficient workflows without requiring changes to existing SCADA infrastructure.

If you’re looking to extend SCADA’s reach and strengthen daily field operations, Wave9 can support your team without disrupting your current control systems. Contact Us